AI-Powered Digital Twins for SmarterIndustrial Operations

Transform your plant performance with deep learning models that optimize processes, reduce costs, and drive sustainable operations.

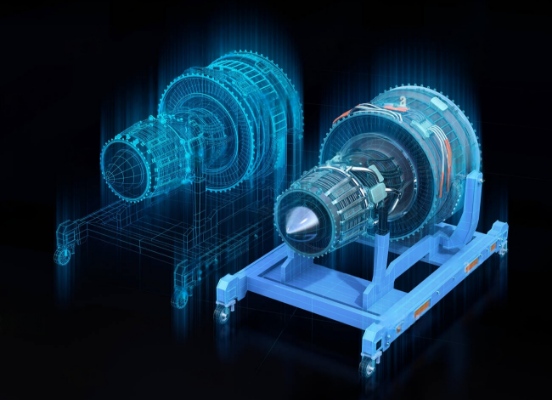

Meet Your Plant's Digital Twin

DigiTwin creates an AI-powered digital replica of your industrial operations that continuously learns and adapts. Our platform easily connects to your existing plant data systems and uses advanced deep learning models to influence your process parameters in real-time.

Unlike conventional solutions, our digital twins don't just monitor - they provide actionable recommendations and can even implement changes autonomously through closed-loop automation. This results in significant cost savings across key areas like energy usage, waste reduction, and emissions control.

With DigiTwin.ai, you gain a 24/7 AI-powered digital workforce that can analyze operational data, predict maintenance needs, and optimize processes - all while your team focuses on strategic growth initiatives.

Why Industry Leaders Choose DigiTwin

Our platform delivers measurable results through advanced AI technology and deep industrial expertise.

Rapid Implementation

Connect to most plant DCS and APC systems out of the box, with tangible improvements realized within weeks, not months.

Significant Cost Savings

Our clients typically see 15-25% reduction in energy costs, 30-40% decrease in unplanned downtime, and 20-30% improvement in overall operational efficiency.

Eco Efficiency

Reduce emissions and waste while optimizing resource usage, helping you meet environmental targets without sacrificing performance.

Continuous Improvement

Our AI models learn continuously from your operational data, adapting to changing conditions and finding new optimization opportunities over time.

Data-Driven Insights

Leverage real-time analytics and predictive intelligence to uncover bottlenecks, forecast failures, and guide smarter decisions across the plant floor.

Scalable Across Units

Whether it's one production line or multiple plants across geographies, DigiTwin.ai scales seamlessly to deliver consistent performance optimization wherever it's deployed.

Industries We Serve

Our digital twin solutions are tailored to address the unique challenges of your specific operational setup.

Cement Industry

Boost productivity, enhance energy efficiency, and improve product quality with digital twins designed for complex cement and chemical processes.

Learn more

Water & Utilities

Enhance operational efficiency, reduce costs, and optimize energy use with predictive digital twins for critical utility processes.

Learn more

Fertilizer Industry

Accelerate quality control, improve process visibility, and enable faster decision-making with AI-powered digital twins for complex chemical processes.

Learn more

Food & Beverages

Improve asset reliability, minimize losses, and optimize energy usage with intelligent digital twins for food and beverage operations.

Learn moreReal Results from Real Clients

See how leading companies are transforming their operations with DigiTwin.ai.

Global Cement Manufacturer Optimizes Production Efficiency

A leading global conglomerate adopted DigiTwin.ai's Digital Twin solution to optimize their cement manufacturing process. Within months, they achieved: