A System Built for Autonomous Industrial Operations

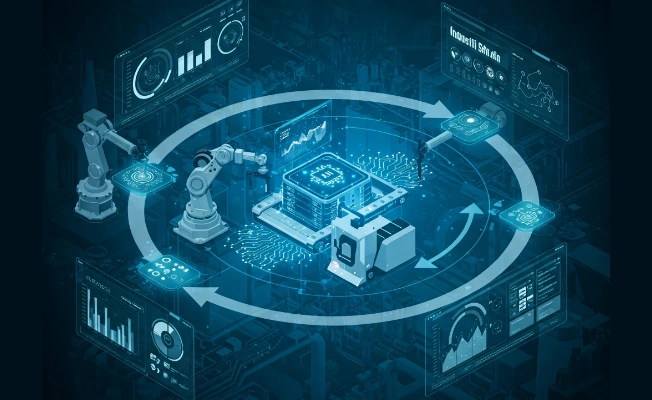

DigiTwin.ai has developed a revolutionary platform that creates digital twins of your industrial operations, enabling unprecedented levels of insight, optimization, and automation. We understand every organization is different, so we have built our platform to be highly customizable to cater to your unique challenges and requirements.

How DigiTwin.ai Works

Our platform creates a comprehensive digital replica of your industrial operations by integrating real-time sensor data with AI-powered analytics. This digital twin continuously learns from your operational data, identifying patterns and optimization opportunities that would be impossible to detect manually.

The DigiTwin.ai platform consists of three core components that work together to transform your operations:

Real-Time Industrial Intelligence

Monitors your operations 24/7, providing immediate visibility into performance issues

Closed Loop Automation

Uses reinforcement learning to make autonomous decisions that optimize processes

AI-Powered Digital Workforce

Deploys AI agents to analyze data, predict maintenance needs, and solve problems

Real-Time Industrial Intelligence

Control Tower for Operations

At DigiTwin.ai, we've built the most advanced industrial intelligence network, integrating real-time sensor data with AI-powered analytics to enable a control tower for your operations. The control tower is capable of processing massive operational datasets concurrently to provide visibility to acute issues that affect performance.

Live Monitoring

Track equipment or process performance and production efficiency in real-time dashboards

Process Control Alerts

Text or email alert when there is a deviation in key performance indicators

Performance Benchmarking

Compare current performance against historical data and industry standards

Root Cause Analysis

Quickly identify the source of performance issues or quality deviations

Closed Loop Automation

Autonomous Decision-Making with Reinforcement Learning

Our models are designed to learn continuously from your operational data over time and can adapt dynamically to changing conditions. There is a simplified Machine Learning Operations (MLOps) set-up within the platform that can be handy for your in-house team to switch between models based on your master production schedules.

Companies running our closed loop automations have reported:

Enhanced Efficiency

Continuously optimizes processes in real-time, reducing manual interventions and improving operational performance.

Increased Accuracy

Automated adjustments based on real-time data minimize errors and ensure consistent output quality.

Cost Savings

Reduces waste, energy consumption, and downtime by dynamically optimizing resources and processes.

AI-Powered Digital Workforce

Unlock 24/7 Automation with AI-driven Digital Workers Using LLMs

DigiTwin.ai brings the power of AI agents to analyze your operational data and search your historical data library effectively for the right information. While your team focuses on strategic growth, our Digital Workforce can take care of:

Faster Issue Resolution

Quickly analyze and diagnose maintenance problems, providing immediate solutions or recommendations to reduce downtime.

Predictive Maintenance

Analyze historical data to predict potential failures, allowing for proactive maintenance and minimizing unexpected breakdowns.

Knowledge Management

Capture and utilize institutional knowledge to improve decision-making and operational consistency.

Continuous Monitoring

Provide 24/7 vigilance over operations without human fatigue or oversight.

Getting Started with DigiTwin.ai

Implementing our digital twin solution is a straightforward process designed to minimize disruption to your operations while maximizing value:

Initial Assessment

1-2 weeks

We analyze your current systems, data sources, and key performance indicators to identify the highest-value applications for digital twins in your operations.

Data Integration

2-4 weeks

Our team connects the DigiTwin.ai platform to your existing systems, ensuring seamless data flow without disrupting operations.

Model Training

3-6 weeks

We train our AI models on your historical and real-time data, customizing them to your specific processes and objectives.

Deployment & Validation

1-2 weeks

The digital twin is deployed in parallel with your existing operations, allowing for validation and fine-tuning without risk.

Continuous Improvement

Ongoing

Once deployed, our platform continues to learn and adapt, with regular updates and optimizations based on performance data.

Seamless Integration with Your Existing Systems

DigiTwin.ai is designed to work with your current technology stack, not replace it. Our platform integrates with:

Control Systems

DCS, SCADA, PLC systems from major vendors, including Siemens, ABB, Honeywell, Emerson, and Yokogawa

Historians

OSIsoft PI, Honeywell PHD, AspenTech IP.21, and other time-series databases

ERP Systems

SAP, Oracle, Microsoft Dynamics, and others

MES Systems

Siemens SIMATIC IT, Rockwell FactoryTalk, GE Digital, and others

IoT Platforms

AWS IoT, Microsoft Azure IoT, Google Cloud IoT, and custom IoT implementations

Custom Systems

Our flexible API architecture allows for integration with proprietary or legacy systems